I mounted the outside pieces of the door jambs to complete them today. Before mounting them I needed to install rivnuts on the remaining tabs outlining the chin windows. The door trim needed to be mounted before I could mount the landing gear because they frame the shock mount for the gear. I used a bit of Hysol to attach them to the frame. I riveted the trim pieces together and used screws to hold the pieces tight while the Hysol set up.

The next project for the day was to fix the issue with the radio stack. My support brace for the radio stack covered a slot that is required for the GTR 200 radio.

So, I needed to remove the brace and cut a slot in it to match the slot

in the radio tray. I marked the slot with a fine point marker before

disassembly and then used my band saw to cut the slot. Then did the

other side. It worked out well.

I was able to insert the tabbed piece into the slots as required.

The GMA 245 audio panel and GTR 200 radio plugs and back plates installed.

Another shot of the slot and back plates installed.

Next up was to reinstall the LED lighting for the cabin. It was pretty straight forward after cleaning the truss with some Acetone. Got them lined up and stuck down pretty good. I hooked them up and tested the switch, it works! They don't throw an immense amount of light but when it's dark they'll be awesome!

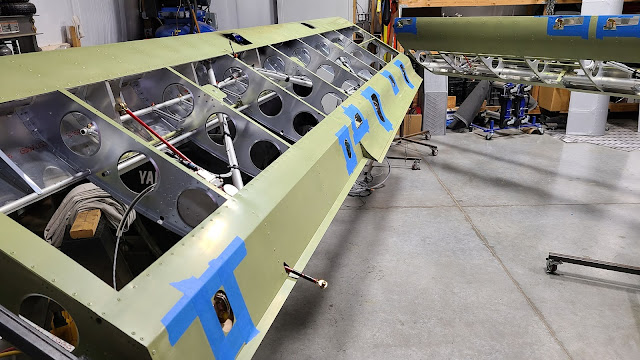

Last project for the day was to paint the wing openings. I worked on taping, hanging plastic and cutting up pieces of construction paper to protect cables and other items I didn't want to paint. A slow process but I got most of one wing done. I did part of the other wing yesterday. I'll finish up tomorrow, then it's time to start gluing the wings for covering.