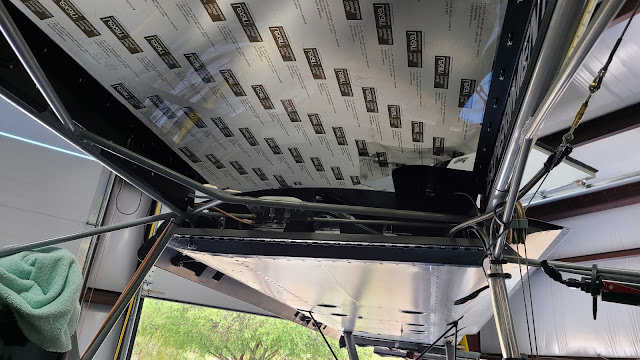

I picked up the Lexan skylight from the tint shop a few days ago and let it cure before installing it. Today, I finished up re-installing the skylight after smoothing the edges a bit. I also had to re-install the GPS pucks/trays/brackets, and the COMM antennas. Everything went back together nicely and without issue. There are no light leaks as the tint covers beyond each side and makes for a really nice look.

The tint is the current state of the art, top of the heap tint from 3M. It blocks 99.9% of UV, 97% of IR (Infrared which is felt heat). So this should be really nice on hot days, or any day when the sun is beating down. I've left the top (outside) protective film on for now to keep protecting it while I finish the plane up.

I had the Adel clamps and the GPS trays powder coated gray to match the interior frame work and I think it came out really nice.